In the realm of orthopedic rehabilitation, 3D printing has emerged as a revolutionary technology offering personalized solutions for patients with musculoskeletal injuries and conditions. By leveraging the capabilities of additive manufacturing, orthopedic professionals can create custom-designed orthoses, prostheses, braces, and implants tailored to the unique anatomical needs and functional requirements of individual patients. This article explores the applications of 3D printing in orthopedic rehabilitation and its transformative impact on patient care.

Understanding 3D Printing in Orthopedic Rehabilitation

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by depositing successive layers of material based on digital 3D models. In orthopedic rehabilitation, 3D printing enables clinicians to fabricate patient-specific medical devices and implants with unprecedented precision, accuracy, and customization. By translating medical imaging data, such as computed tomography (CT) scans or magnetic resonance imaging (MRI) scans, into digital models, orthopedic professionals can design and produce orthoses and prostheses that precisely match the patient’s anatomy and biomechanical requirements.

Applications of 3D Printing in Orthopedic Rehabilitation

The applications of 3D printing in orthopedic rehabilitation are diverse and encompass various aspects of patient care and treatment, including:

- Custom Orthoses and Prostheses: 3D printing allows for the creation of custom-fitted orthoses and prostheses designed to support, protect, or replace damaged or missing limbs. These devices are fabricated based on digital scans of the patient’s anatomy, ensuring optimal fit, comfort, and functionality. Custom orthoses can provide support and stability for individuals with musculoskeletal injuries or conditions, while prosthetic limbs can restore mobility and independence for amputees.

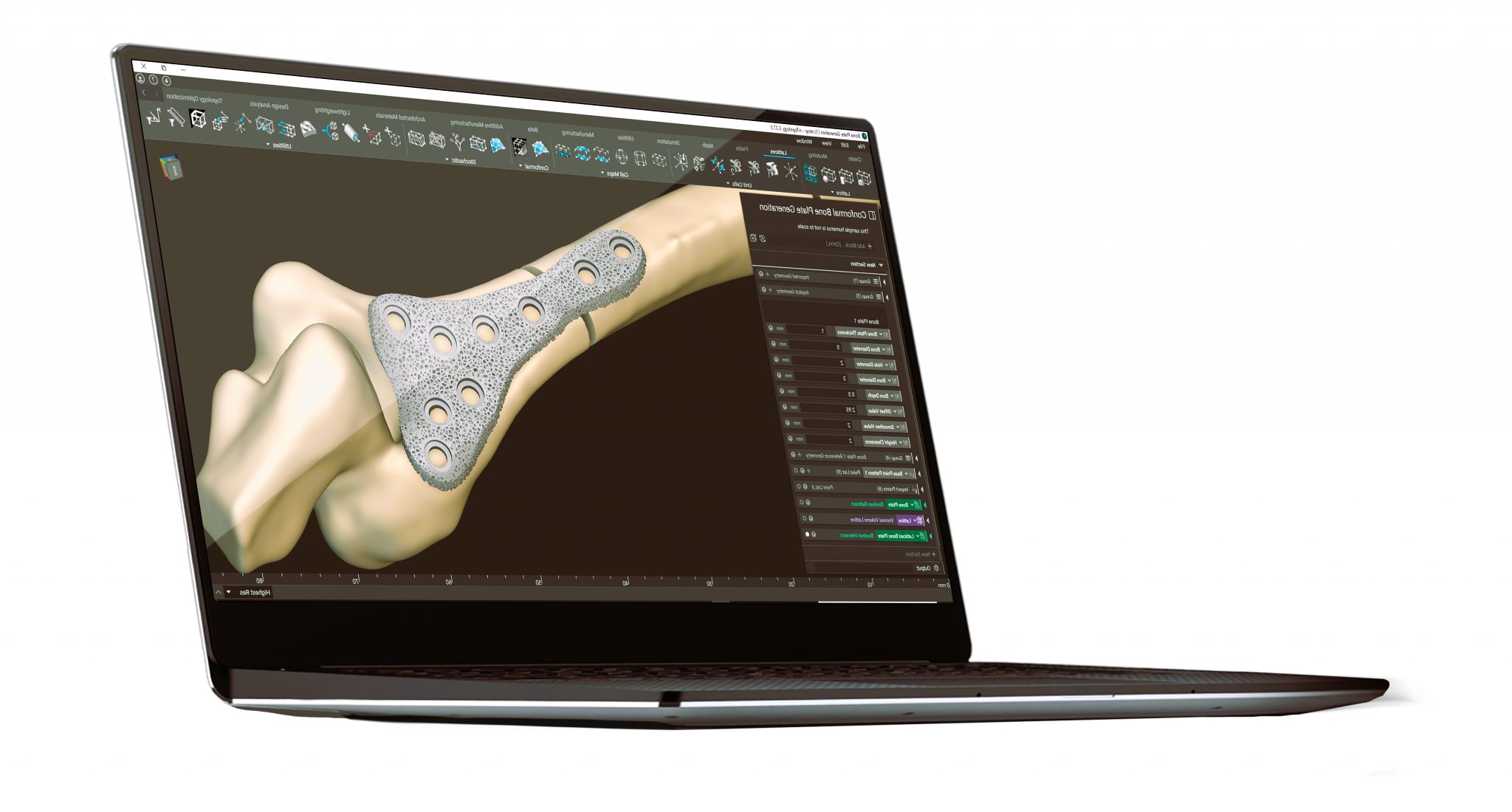

- Patient-Specific Implants: 3D printing enables the production of patient-specific implants for orthopedic reconstruction surgeries, such as joint replacement or spinal fusion. By precisely replicating the patient’s anatomy and pathology, 3D-printed implants offer better fit and alignment, reducing the risk of implant failure, complications, and revision surgeries. Patient-specific implants can improve surgical outcomes, reduce recovery time, and enhance patient satisfaction compared to off-the-shelf implants. Read our article about Biofeedback Devices.

- Functional Braces and Splints: 3D printing enables the fabrication of lightweight, durable, and ergonomic braces and splints designed to immobilize or support injured joints or limbs. These custom-designed devices can provide stability, protect soft tissues, and facilitate healing while allowing for comfortable movement and functional rehabilitation. Functional braces and splints can be adjusted and iteratively refined based on the patient’s evolving needs and recovery progress.

- Anatomical Models and Surgical Guides: 3D printing facilitates the creation of patient-specific anatomical models and surgical guides to assist orthopedic surgeons in preoperative planning and intraoperative navigation. By visualizing complex anatomical structures and pathologies in three dimensions, surgeons can better understand the patient’s anatomy, anticipate surgical challenges, and optimize surgical approaches. Surgical guides ensure precise implant placement and alignment, leading to improved surgical accuracy and outcomes.

Impact on Patient Care and Rehabilitation

The integration of 3D printing into orthopedic rehabilitation has the potential to revolutionize patient care and treatment outcomes in several ways:

- Personalized Treatment: 3D-printed orthoses, prostheses, and implants are tailored to the individual patient’s anatomy, biomechanics, and functional requirements, resulting in better fit, comfort, and performance compared to traditional off-the-shelf devices. Personalized treatment solutions improve patient satisfaction, adherence, and outcomes by addressing the unique needs and preferences of each patient.

- Faster Prototyping and Iterative Design: 3D printing enables rapid prototyping and iterative design of orthopedic devices, allowing clinicians to quickly iterate on design concepts, make modifications based on patient feedback, and optimize device functionality and aesthetics. Faster prototyping reduces lead times and costs associated with traditional manufacturing methods, accelerating the delivery of custom solutions to patients.

- Enhanced Rehabilitation and Functional Outcomes: Custom-designed orthoses, prostheses, and braces optimize biomechanical alignment, support injured tissues, and facilitate functional rehabilitation, leading to faster recovery, improved mobility, and enhanced quality of life for patients. 3D-printed devices promote active participation in rehabilitation activities, allowing patients to regain independence and return to their daily activities sooner.

Challenges and Considerations

Despite its potential benefits, 3D printing in orthopedic rehabilitation faces several challenges and considerations, including:

- Material Selection and Biocompatibility: The choice of printing materials and their biocompatibility are critical considerations in the fabrication of orthopedic devices. Clinicians must select materials that are biocompatible, durable, and suitable for the intended application while minimizing the risk of adverse reactions or complications.

- Regulatory Approval and Quality Assurance: 3D-printed medical devices are subject to regulatory approval and quality assurance standards to ensure safety, efficacy, and reliability. Clinicians must adhere to regulatory requirements and follow established guidelines for device design, manufacturing, sterilization, and post-market surveillance to mitigate risks and ensure patient safety.

- Cost and Accessibility: The cost of 3D printing equipment, materials, and software, as well as the expertise required for design and fabrication, may pose barriers to widespread adoption and accessibility. Efforts to reduce costs, improve affordability, and expand access to 3D printing technologies are needed to maximize their potential impact on patient care and rehabilitation.

Conclusion

3D printing holds immense promise for revolutionizing orthopedic rehabilitation by offering personalized, precise, and patient-specific solutions for musculoskeletal injuries and conditions. By leveraging the capabilities of additive manufacturing, orthopedic professionals can create custom-designed orthoses, prostheses, implants, and surgical guides that optimize patient outcomes and enhance quality of life. As 3D printing technology continues to evolve and become more accessible, its integration into orthopedic rehabilitation practice offers new opportunities for innovation, collaboration, and transformative patient care.

For further information on the standardization of 3D printing technologies in healthcare, visit Wikipedia’s page on 3D printing in healthcare.

By embracing 3D printing as part of a comprehensive approach to orthopedic rehabilitation, clinicians can empower patients to achieve better functional outcomes, faster recovery, and improved quality of life, ultimately enhancing the effectiveness and efficiency of musculoskeletal care.